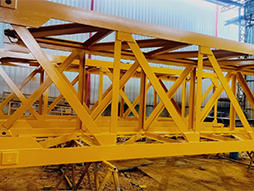

Blasting and painting are essential surface protection techniques used to enhance durability, prevent corrosion, and improve the aesthetic appeal of metal and industrial surfaces. The blasting process removes rust, old coatings, and contaminants, creating a clean and rough surface for better paint adhesion. Common methods include sandblasting, shot blasting, and grit blasting, each suited for different surface treatment requirements. After blasting, high-performance coatings such as epoxy, polyurethane, and zinc-rich primers are applied to provide long-term protection. These techniques are widely used in industries like automotive, construction, marine, oil & gas, and industrial equipment manufacturing. Shree Paint & Coating Industries specializes in providing high-quality blasting and painting services, ensuring superior corrosion resistance and extended lifespan of assets.

| Sr. No | Process | Material | Coating Type | Benefits | Applications |

|---|---|---|---|---|---|

| 1 | Blasting | AL | Abrasive Cleaning | Removes Rust & Impurities | Aerospace Parts, Marine Industry |